Innovative,

technology-powered

structural design

© Robert Benson Photography

The Odeh Blog:

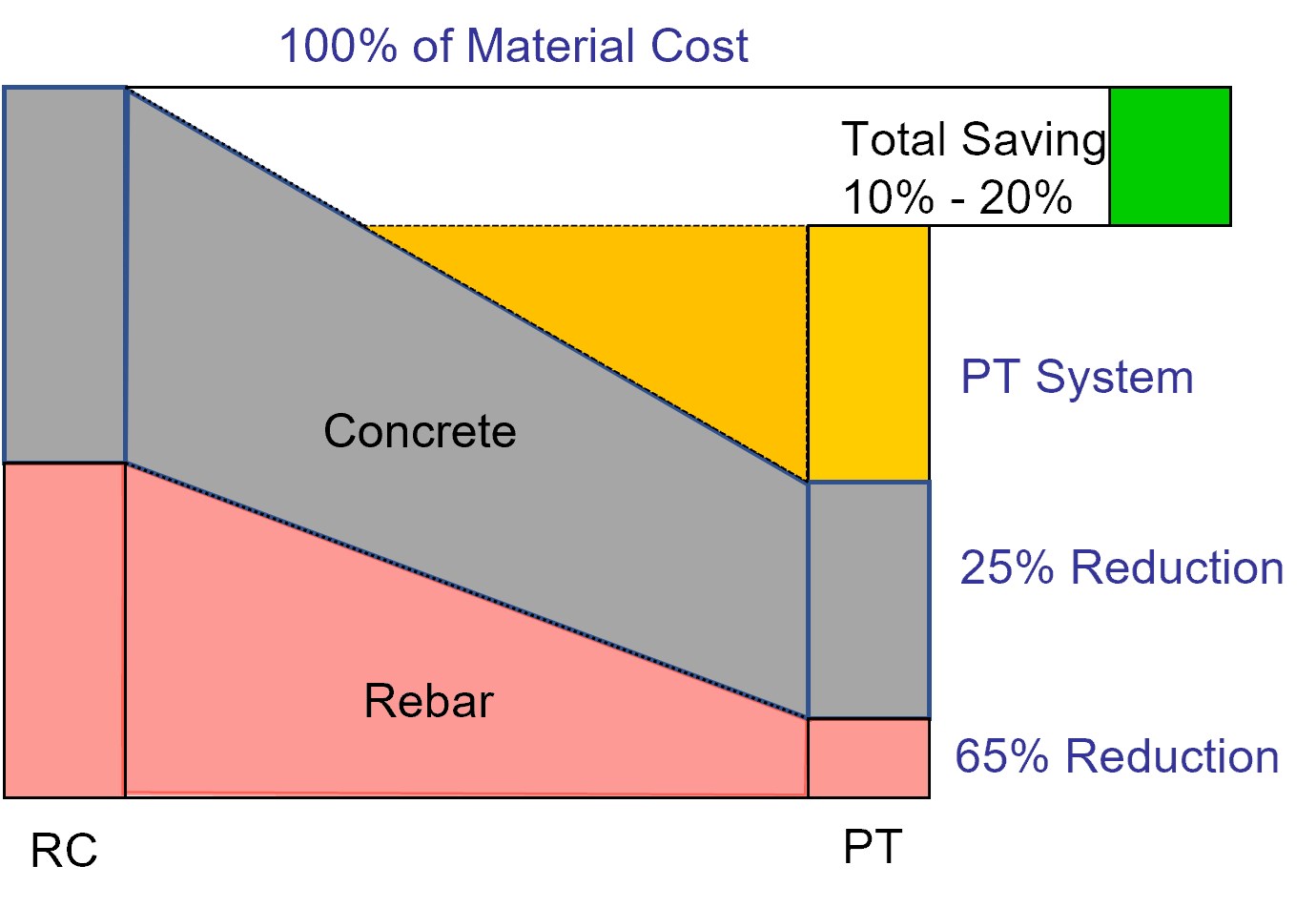

Post-Tensioned Concrete for Sustainable Design, Part I

January 12, 2024

Building a Sustainable Tomorrow: Odeh Engineers' Commitment to SE2050 Challenge and Post-Tensioned Concrete Innovations

READ MORE →

Featured Projects

Our award-winning projects feature creative design solutions, innovative systems, and high-performance structures.

Groton Hill Photo © Robert Benson Photography